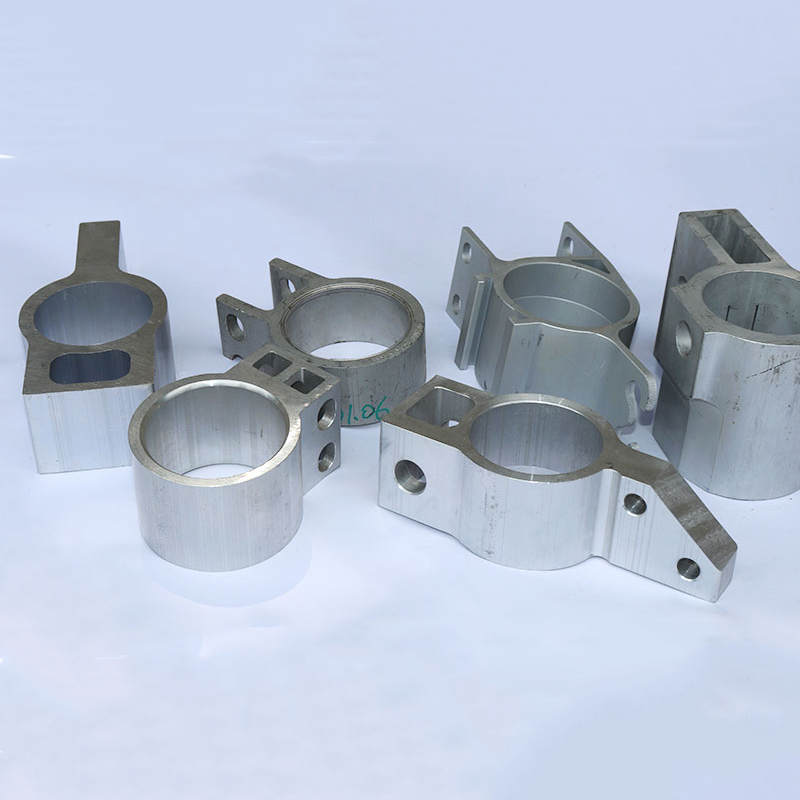

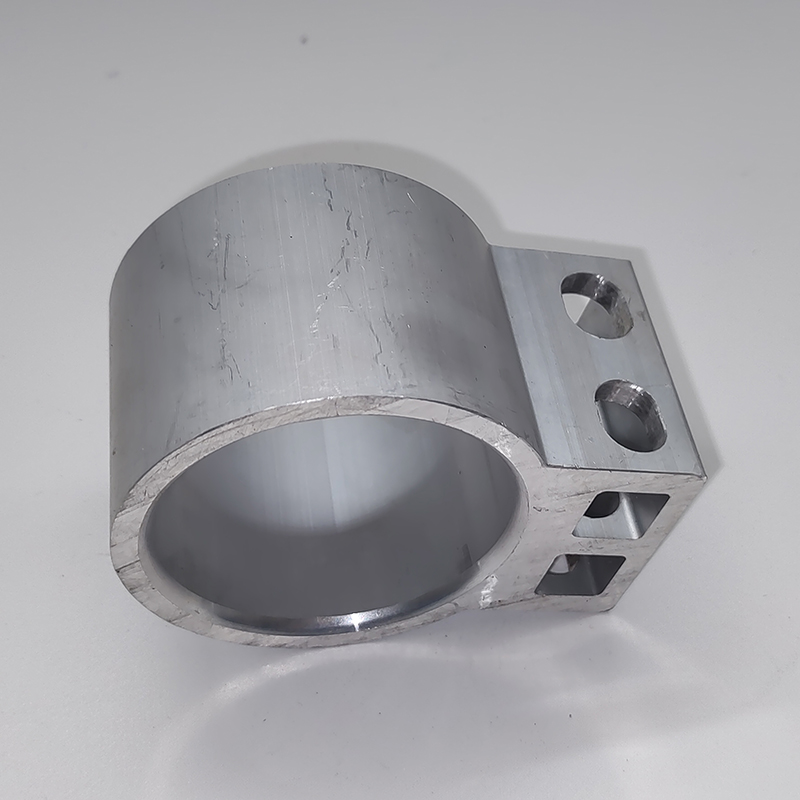

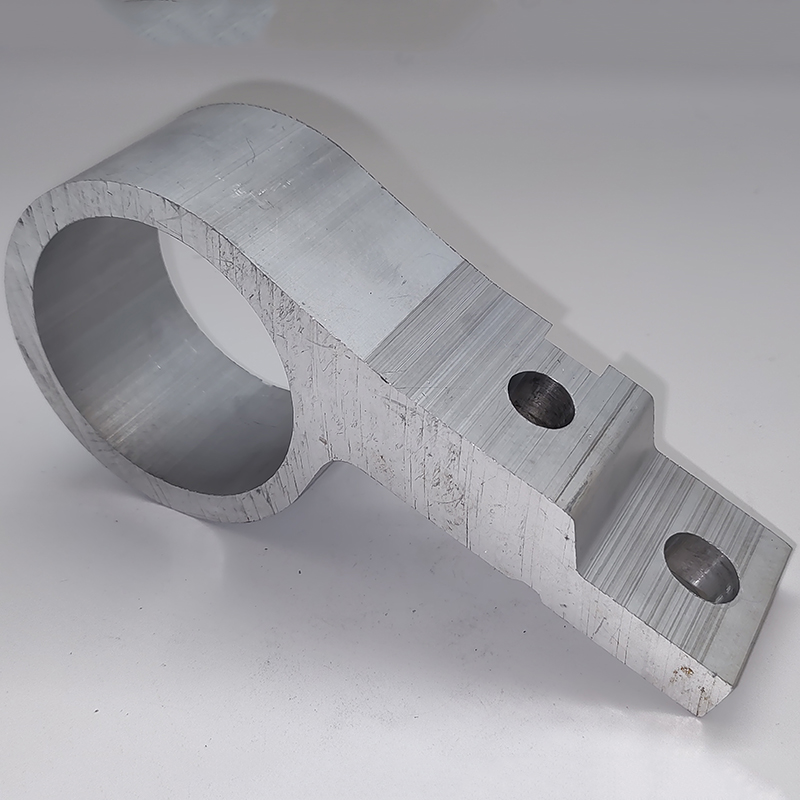

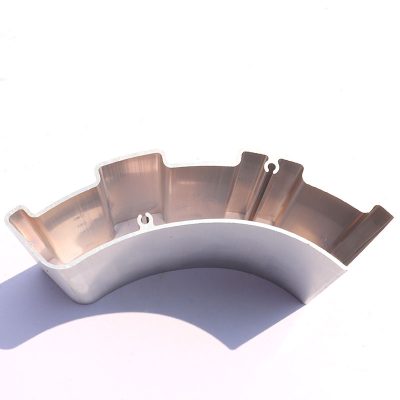

Automotive parts vehicle shock absorber bracket industrial aluminum profiles

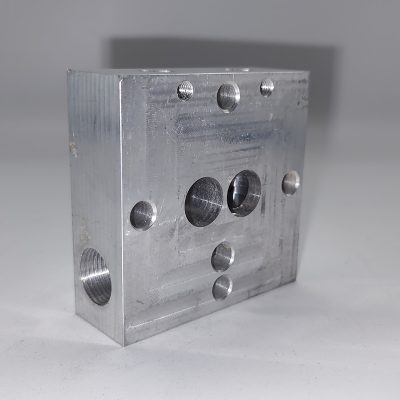

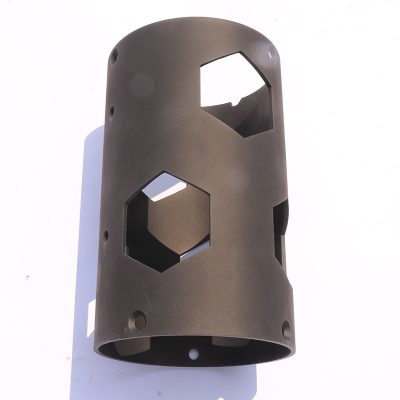

We provide a full range of CNC machining services, extruded profile mold production, and various post-processing work for aluminum parts such as cutting, chamfering, drilling, welding, painting, and anodizing.

The advantages of using aluminum profiles for car shock absorber bushings include:

Lightweight: Aluminum alloy materials have a low density and high strength. Compared with traditional steel bushings, they are lighter, which can reduce the weight of the vehicle, improve fuel economy and driving efficiency.

Corrosion resistance: Aluminum alloy materials have excellent corrosion resistance and can be used in harsh environmental conditions, extending the service life of the bushings.

Good thermal conductivity: Aluminum alloy materials have good thermal conductivity, which can quickly dissipate the heat generated in the shock absorber, avoiding problems caused by overheating.

Good processability: Aluminum alloy materials are easy to process and form, and can meet various shapes and size requirements of shock absorber bushings.

In summary, using aluminum profiles as the material for shock absorber bushings can not only improve the performance and service life of cars, but also reduce vehicle weight, which is in line with the development trend of modern automotive lightweighting.