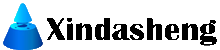

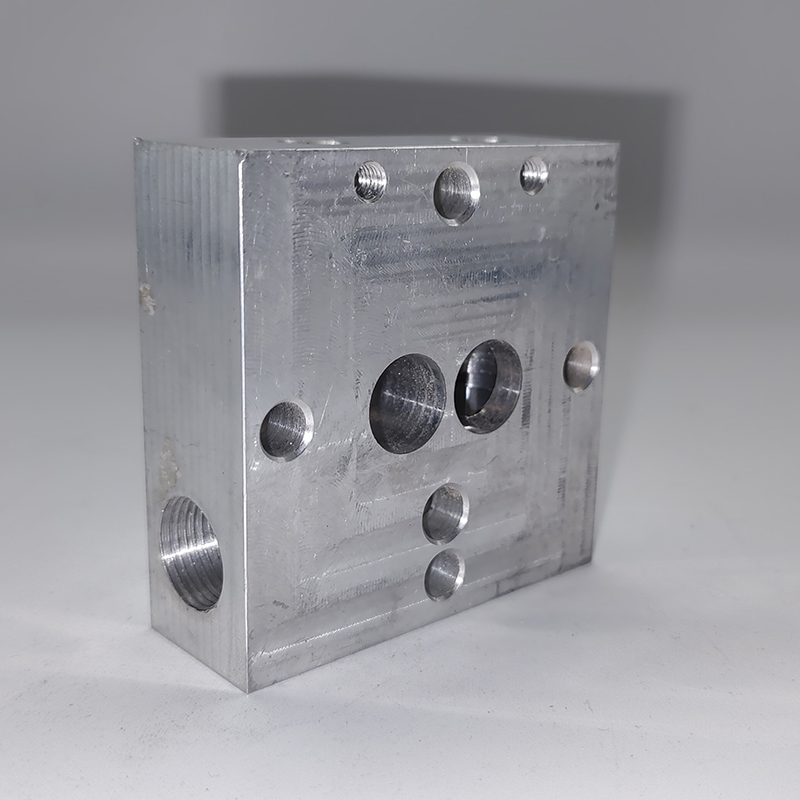

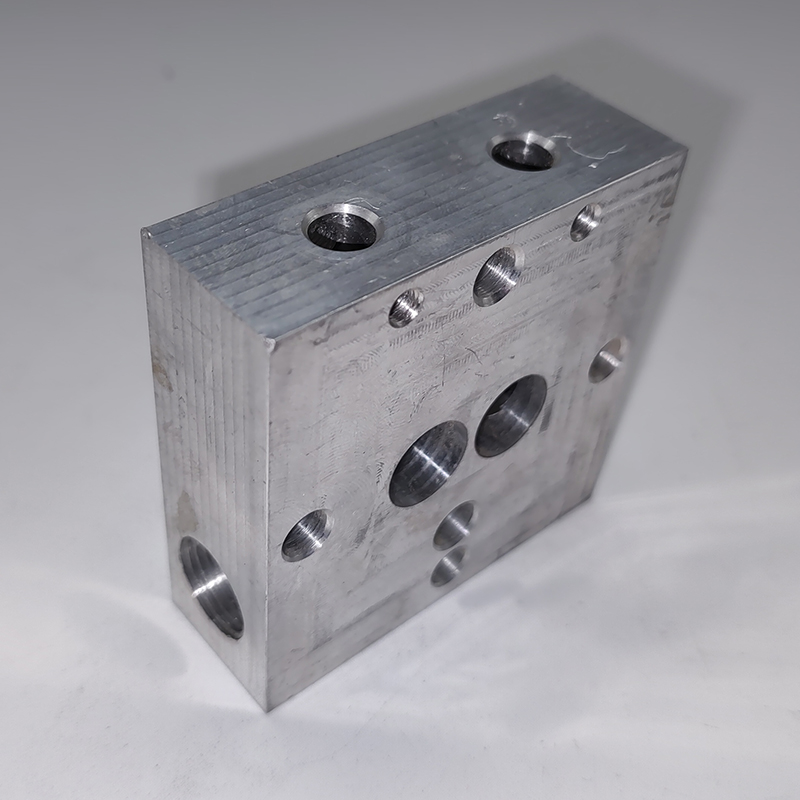

Aluminum cylinder components

Aluminum cylinder components are favored for their lightweight yet durable construction, corrosion resistance, good thermal conductivity, and flexibility in design, making them an ideal choice for a wide range of applications.

Aluminum extrusions are the perfect solution for designing and manufacturing high-performance pneumatic cylinder components. One of the major advantages of using aluminum extrusions for cylinder parts is their lightweight yet durable nature, which makes them ideal for high-speed applications. In addition, aluminum extrusions offer excellent corrosion resistance, ensuring longevity and durability in harsh operating environments.

Another key benefit of aluminum extrusions is their versatility, as they can be easily customized and machined to meet specific design requirements. This means that engineers and designers can easily create custom components to fit unique applications, while also reducing material waste and production costs.

Furthermore, aluminum extrusions offer superior strength-to-weight ratios compared to other materials such as steel, which allows for more efficient and cost-effective designs. They also have excellent thermal conductivity, which enables efficient heat dissipation and helps to prolong the life of components.

Overall, aluminum extrusions provide a superior solution for pneumatic cylinder components, offering a combination of strength, durability, and customization options that are unmatched by other materials. With their lightweight yet robust design, excellent corrosion resistance, and versatility, aluminum extrusions are the ideal choice for high-performance cylinder parts.